|

|

|

|

|

|

||

|

|||||||

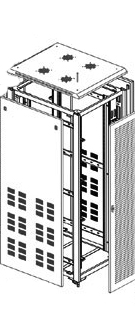

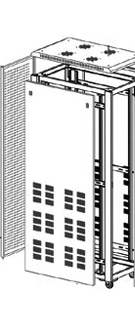

Whatever be your requirement in sheet metal fabrication, PSW can control the close tolerances that brings precision to your manufacturing operations. We can fabricate components from a variety of metal products including Aluminium, Stainless steel, Cold Rolled Steel and Pre plated Materials. Our assembly department produces electro-mechanical assemblies either complete or in kit form. We have a select group of high quality suppliers with whom we work closely to choose the right components for your needs. Nothing leaves the PSW's workshop floor without full inspection and certification by our skilled in house technicians. When PSW components arrive at your production line you know that they have been given quality approval by the most critical and exacting inspectors in the business.

PSW offers high end engineering & design solutions. Our design teams are highly skilled & trained engineers with good experience in the sheet metal industry and it provides documentation & engineering support to our production team. With 8 skilled design engineers, PSW uses design softwares like Solid works, Think 3, Fabriwin, with Solid modeling to transfer the customer drawings quickly & accurately to manufacturing requirements in terms by preparing flat drawing analyzing the feasibility of manufacturing, preparing PPAP, BOM followed by control charts. PSW uses CAD CAM and other softwares namely:

- Metals Soft

- Fabriwin

- API00

- Solid Works

Facilities at PSW consists of the following processes:

Punching:

CNC Punching from 0.8 to 3.00mm width of 1250 x 2500mm without repositioning. More than 2500mm width is also possible.

BENDING:

Components can be bent up to 3mm of any material with an accuracy of 0.2mm by using CNC Bending Machine.

CNC Bending 0.8 to 3.00mm steel sheet for the length of 2.5m with tab folding accuracy of ±0.2mm.

RIVETING:

The process of riveting to fix the fasteners like PEM fasteners, Clifa fasteners, etc., by using high accuracy NC controlled PEM inserting machines from LCM Control, Haeger and Pemserter.

SPOT WELDING:

- Spot welding of steel thickness from 0.8 to 3.00mm.

- Aluminium spot welding of 3+3mm thickness.

TIG & MIG WELDING:

TIG & MIG Welding for aluminium, aluminium alloy and stainless steel.

FABRICATION:

High quality precision sheet metal fabrication with the following metals

- CRCA

- G. I. Sheets

- Stainless Steel

- Aluminium

- HRCA

POWDER COATING:

Dedicated source. One complete solution of finished process with automatic conveyorised facility and nano-technology of pre-treatment. The plant can handle the maximum cubicle size of 3x2x2m.

Proposed Facility:

- CNC Laser Machine

- 7 Axis Bending Machine